Quality System

Quality Policy

Hoosier Precision Machining consistently strives to provide the highest quality plastic and metal components for our industry. These services always meet or exceed our customers’ requirements while remaining in full compliance with the ISO9001, AS9100, and ISO13485 quality management standards. Our highly trained and fully qualified personnel remain actively involved in our continual improvement program. Further, we pledge to maintain a safe and environmentally friendly workplace in recognition of our responsibilities to our employees, our customers, and our community.

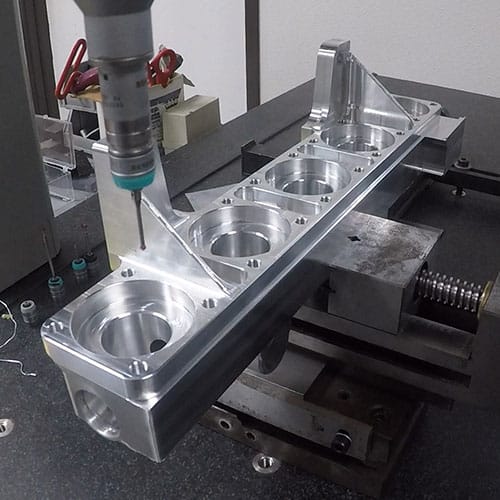

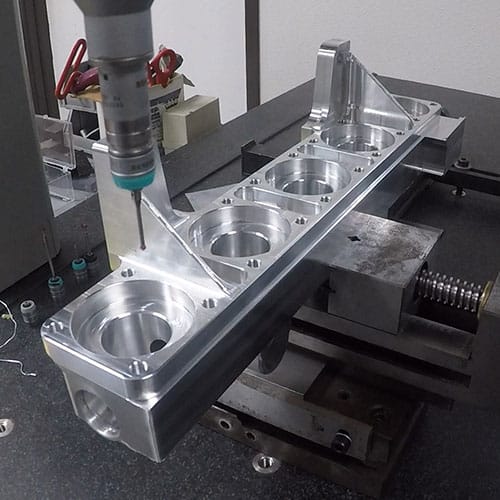

Quality Control Lab

Our quality lab utilizes state of the art software and equipment to ensure product precision. We have first, final, and in-process inspectors in each department who verify that your parts are manufactured and made to print. In addition to wide array of hand inspection tools, our quality control equipment includes:

1 – Brown & Sharpe Global Image rigid CMM

1 – Hexagon ROMER RS3 Absolute Arm with fully integrated and certified RS3 laser scanner

1 – Micro VU M436 precision video measuring machine

1 – GP Flash 302 Smart Scope which features axial straightness and perpendicularity

1 – Keyence IM 6225 Image Dimensional Measuring System

4 – Mitutoyo PHA14 Comparators with a 10X magnification

DOWNLOAD OUR ISO 9001:2015 + AS9100D CERTIFICATE

DOWNLOAD OUR ISO13485:2016 CERTIFICATE

DOWNLOAD OUR PURCHASE ORDER QUALITY CLAUSES